Membrane Switch Technology: The Trick to Reliable and Cost-Effective Interfaces

Membrane switch modern technology has actually arised as a pivotal part in the style of user interfaces, providing both integrity and cost-effectiveness across a diverse array of applications. As we explore the diverse advantages of membrane layer switches, their possibility for development elevates concerns regarding future applications and evolving trends.

Understanding Membrane Layer Switch Innovation

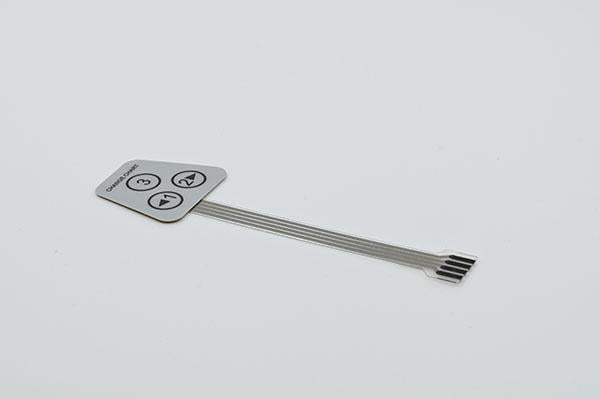

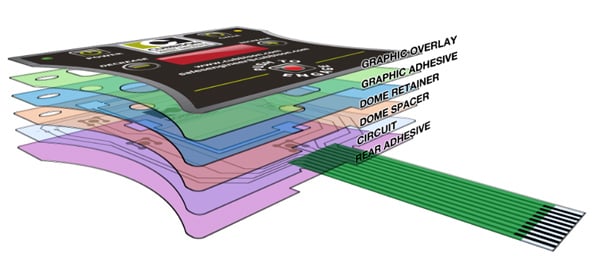

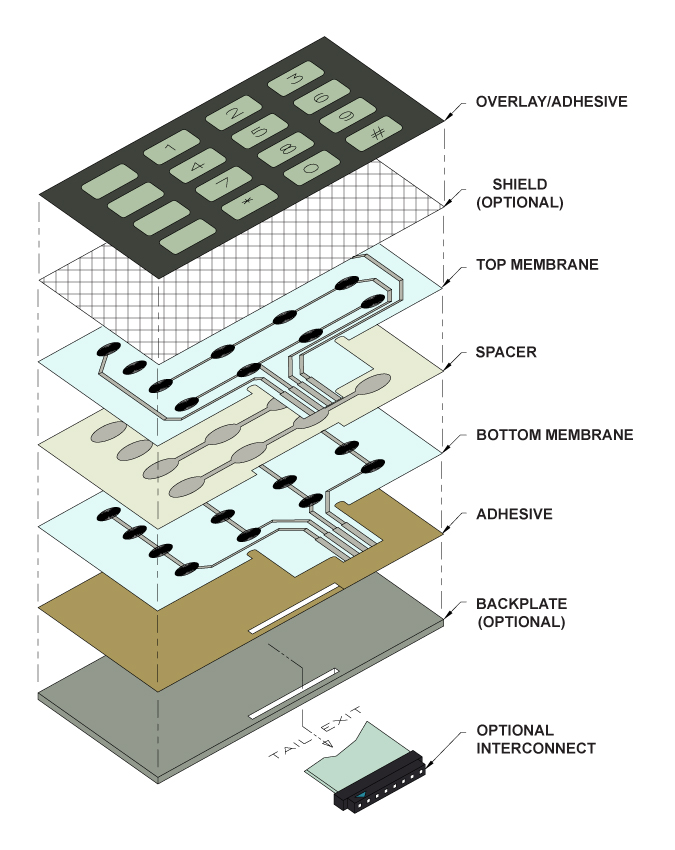

Membrane layer switch modern technology is an extensively utilized user interface solution in numerous electronic devices, providing a seamless mix of performance and layout. This technology incorporates numerous layers of products, usually including a graphic overlay, spacer layer, and a circuit layer. The graphic overlay displays the user interface components, while the spacer layer separates the circuit layer from the overlay until an individual turns on a button.

When stress is put on the overlay, the circuit layer completes the electrical circuit, sending a signal to the gadget. This device enables numerous configurations, including responsive feedback and backlighting choices, boosting user communication. Membrane layer buttons are commonly manufactured using durable products such as polyester or polycarbonate, guaranteeing longevity and resistance to ecological elements like wetness and dirt.

The adaptability of membrane layer switches over allows their application in diverse markets, including medical devices, consumer electronic devices, and commercial controls. Their portable layout enables combination right into space-constrained atmospheres, giving an effective interface without jeopardizing aesthetic allure. Recognizing the intricacies of membrane button modern technology is vital for manufacturers and designers looking for to create trusted and reliable human-machine user interfaces.

Key Advantages of Membrane Switches

While different user interface remedies exist, membrane layer switches offer distinct advantages that make them a recommended choice in numerous applications. Among the primary advantages is their durability; membrane layer switches are created to stand up to rough environmental problems, including wetness, dust, and temperature variations, guaranteeing long-lasting efficiency. This strength considerably reduces the demand for frequent replacements, thereby decreasing total upkeep expenses.

In addition, membrane switches are light-weight and small, making them ideal for applications where room is limited. Their inconspicuous design adds to a sleek look without endangering functionality.

Cost-effectiveness is additionally a significant benefit, as the production procedure for membrane changes has a tendency to be more economical compared to standard mechanical switches. This affordability, combined with their reliability and convenience of setup, placements membrane layer changes as a useful remedy for a large range of sectors looking for reliable and reliable user interfaces.

Applications Across Various Industries

Exactly how do membrane layer switches adapt to the varied requirements of numerous industries? Membrane layer button modern technology is progressively recognized for its convenience, making it suitable for a large variety of applications throughout multiple markets.

In customer electronic devices, membrane buttons give a compact remedy for push-button controls and home appliances, boosting individual experience via user-friendly style. Additionally, the commercial sector leverages membrane layer buttons for equipment control panels, gaining from their resistance to harsh atmospheres, such as wetness and dust.

Army and aerospace applications also utilize membrane layer switches for their dependability and capability to stand up to severe conditions, ensuring operational effectiveness in essential circumstances. The food and beverage market embraces these buttons for automated systems, where sanitation and ease of operation are critical (membrane switch). Ultimately, membrane buttons are tailored to fulfill the one-of-a-kind needs of each market, proving their vital function in modern innovation user interfaces

Layout and Modification Choices

In the realm of membrane layer switch innovation, layout and personalization choices play a critical duty in enhancing functionality and customer interaction. These buttons can be tailored to meet specific operational requirements and visual preferences, making them functional elements in different applications.

Among the primary modification alternatives is the format of the switch itself, which can be made to suit special interface and ergonomic considerations. By adjusting the form, dimension, and arrangement of switches, makers can create intuitive layouts that assist in simplicity of usage. Furthermore, the incorporation of different colors and graphic overlays permits for branding and improved presence, making certain that users can promptly recognize functions.

Moreover, membrane switches can be engineered with numerous responsive feedback devices, such as Related Site raised switches or audible clicks, to enhance the individual experience. Various products can additionally be selected for sturdiness and environmental resistance, attending to elements such as wetness, temperature level variations, and chemical direct exposure.

Inevitably, the considerable layout and customization options readily available in membrane button innovation equip organizations to produce customized remedies that not only meet practical needs yet also line up with their branding and operational demands.

Future Trends in Membrane Buttons

As membrane layer button innovation remains to develop, future patterns are progressively concentrated on enhancing user experience and integrating advanced performances. One considerable trend is the assimilation of touch-sensitive and capacitive innovations into conventional membrane switches. This growth permits more user-friendly customer interfaces, giving responsive comments while maintaining a sleek style.

An additional arising fad is using eco-friendly products, driven by the expanding demand for sustainable production techniques. Manufacturers are looking for to reduce their carbon footprint by making use of recyclable substrates and low-impact inks, lining up with global sustainability objectives.

In addition, the surge of the Net of Things (IoT) is triggering the consolidation of wise attributes into Look At This membrane switches. Enhanced connection options will certainly make it possible for gadgets to connect with each various other, enabling smooth integration right into more comprehensive systems.

Furthermore, innovations in printing technologies, such as digital printing, are enabling better design versatility and customization. This enables manufacturers to produce intricate designs and dynamic colors cost-effectively.

Conclusion

In verdict, membrane layer switch modern technology stands for a vital development in individual interface design, using significant advantages in sturdiness, modification, and cost-effectiveness. Its extensive applicability across diverse markets underscores its value in contemporary technology. As innovations continue to arise, especially in touch-sensitive interfaces and lasting materials, the potential for membrane changes to boost individual experience and capability continues to be promising. Continued expedition of this innovation will likely yield additionally renovations and expand its range in check my source future applications.